Project Catalogue

Just for Fun - Bringing Ideas to Life:

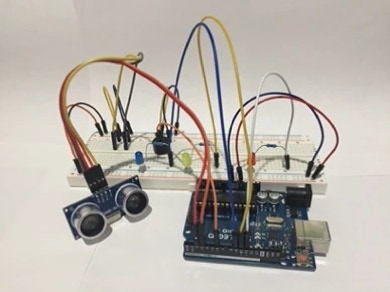

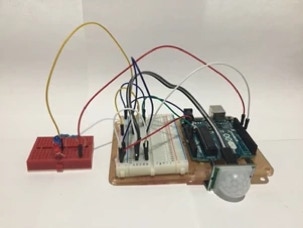

Keyless Piano -

I was inspired to do this project by my friends and their band, The Rumours. I created an Arduino circuit that reads the distance to your hands, and responds with an output of a specific hertz frequency from a piezo buzzer. It requires some fine tuning to produce more notes but it is a work in progress.

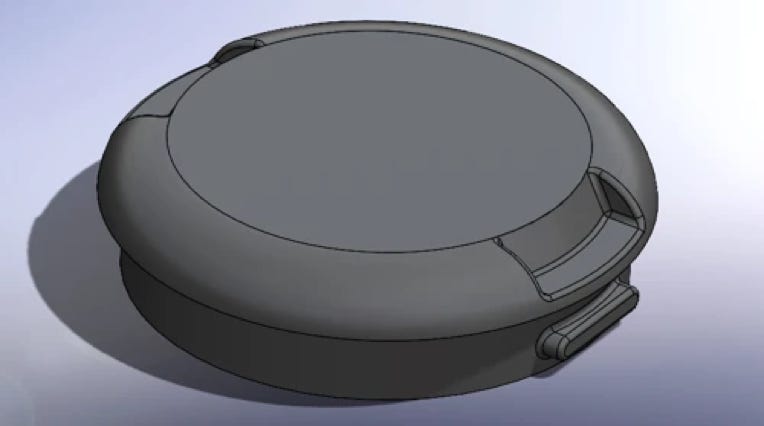

Oil Cap Replacement (v2) for Our Boston Whaler -

Spring 2020 allowed my dad and I to swap our old Mercury 60hp for a newer Yamaha 90hp outboard engine. Unfortunately, in transport the oil cap on the engine cowl broke due to poor efforts tying down the engine in the back of my pickup. My dad and I agreed that the best solution for the time being was the oldest trick in the book; duct tape. Since then, in my spare time, I have been working on a replacement cap in Solidworks to later be manufactured and fitted with a rubber gasket to completely seal the cap to the cowl.

3D Scan and Print -

I wanted to explore the capabilities of iPhone apps and I was able to find this scanning software, Trnio. After a successful scan, printing this watering can proved to be…interesting. I am seeking ways to incorporate this into a larger project.

Lehigh University Graduate Projects:

3D Printer Assembly -

As a part of Covid-curriculum, Lehigh University sent students a 3D Printer. The assignment was only to assemble this machine, but I was too excited to leave it idle.

This printer is now the backbone of most of my small tinkering projects.

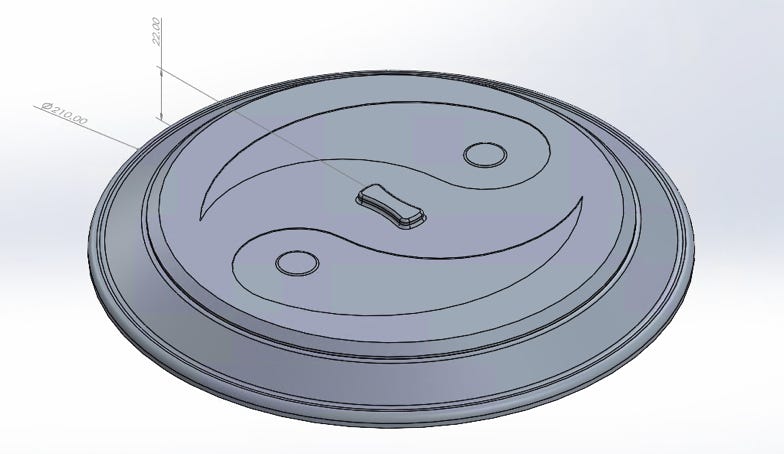

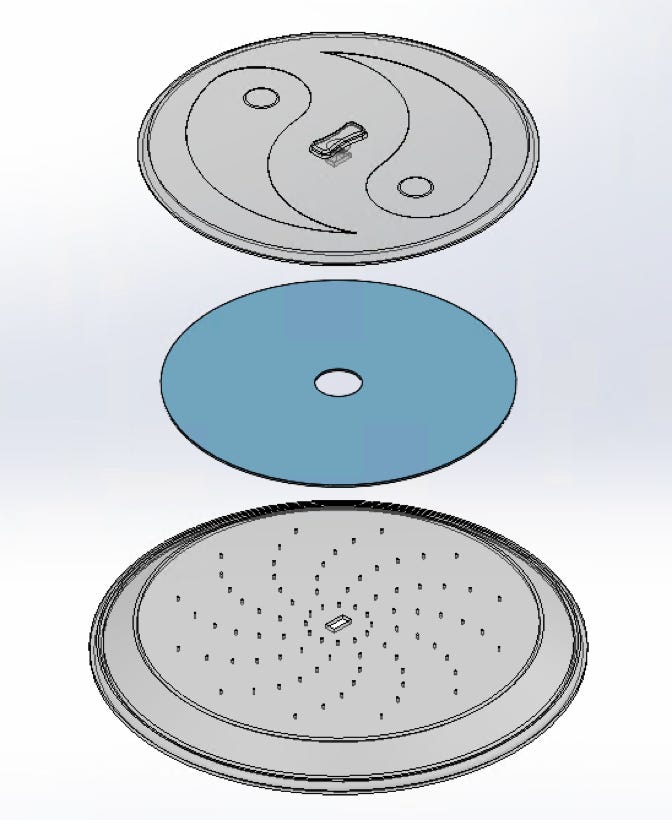

Desiccan -

A product based around one simple concept; food free of sogginess. The two piece lid houses a reusable, interchangeable desiccant to absorb condensation - leaving food hot and crispy upon delivery.

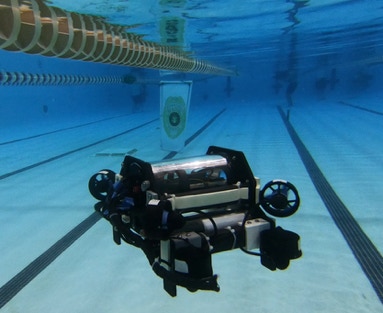

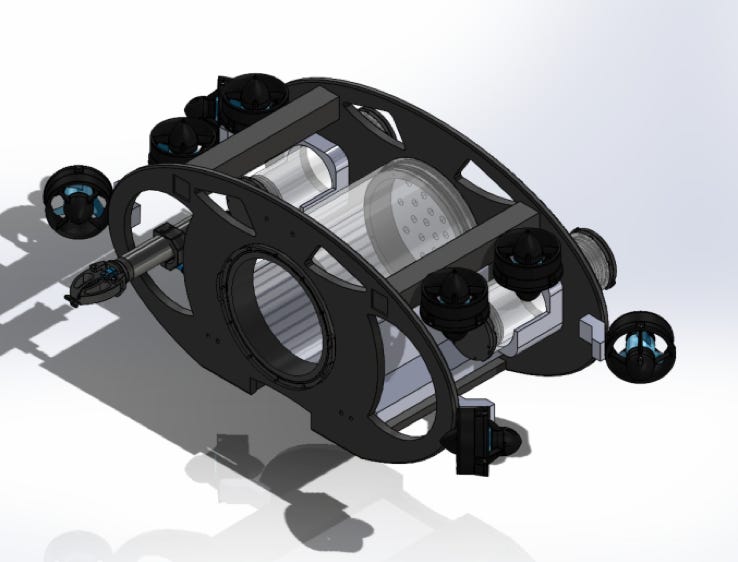

Autonomous Underwater Vehicle (AUV) -

As a part of a Creative Inquiry course, I was able to join a team to aid in all things design, mechanical, testing, and assembly of a custom built “RoboSub” to compete in a competition.

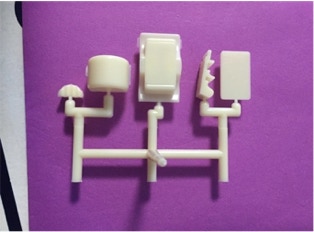

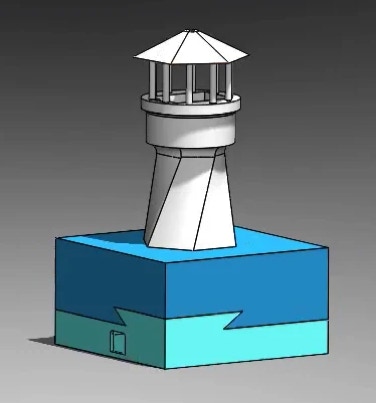

“Smart” Lighthouse -

I created this CAD model to envelope a circuit designed to passively measure light levels and run a 30 minute program when activated. The large box at the bottom is a dovetail box, allowing wires to pass through the main body of the lighthouse to the breadboard at the top of the lighthouse (printing/assembly pending).

Product Placement -

Using Adobe Dimensions, I was able to create a virtual product with a real-life backdrop. In this specific scenario, I had forgotten my apple juice this morning fishing trip, so I added some in for posterity sake.

Lehigh University Undergrad Projects:

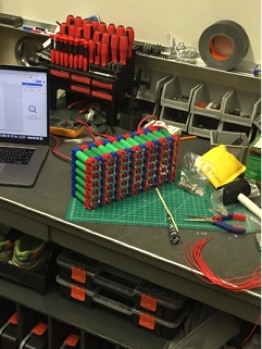

Regenerative Braking for an Electric Motorcycle -

Step 1: Mount Hub Motor.

Step 2: Carefully assemble individual lithium ion cells into a 72 Volt battery. This process was shockingly informative.

Step 3: Design and fabricate metal inertial plates.

Step 4: Full assembly and test.

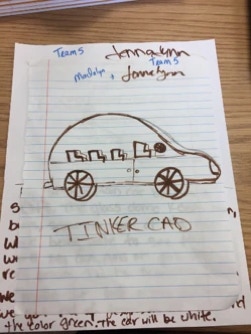

“Hot Wheels” Car -

My team and I were assigned a group of middle schoolers who were responsible for providing us with their dream car. We then proceeded to make CAD models from which the middle schoolers chose a design. After creating toolpaths and using a CNC machine to create our mold, we were able to successfully injection mold their product. The middle schoolers then painted and raced their cars in a “May Madness” tournament.